Compare at:

$3,239.00

Johnny's Price:

$2,399.00

None

Selected

Qty: 1

Qty: 1

More options

keyboard_arrow_down

keyboard_arrow_up

keyboard_arrow_down

Price with selected options:

Where Can I See This Product in Store?

moreThis product is not on display in our showrooms.

Estimated Delivery Price

Enter your zip code to get a delivery estimate.

Ask a Question

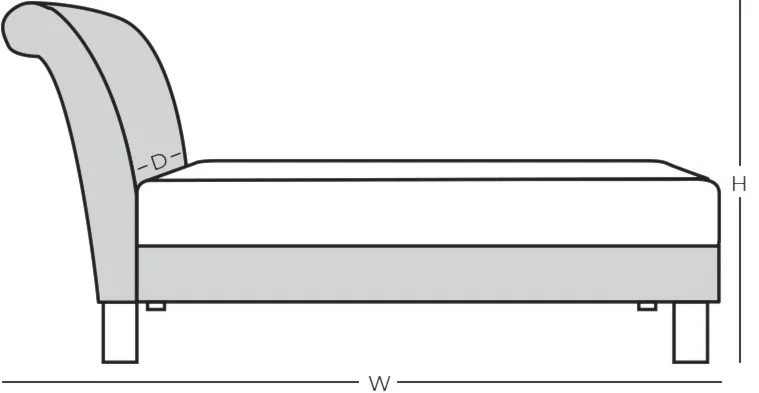

lessDimensions:

30.5" W

×

67" D

×

36.5" H

| Width (side to side) | 30.5 |

| Depth (front to back) | 67 |

| Height (bottom to top) | 36.5 |

| Seat Width | 21 |

| Seat Depth | 50 |

| Seat Height | 19.5 |

| Arm Height | 25 |

Disclaimer

Description

moreThe Pleasanton Chaise shows off its classic influence in its elegant scrolled back and English-style arms. A border of contrasting welt cords can be chosen and forms a beautiful highlight to the arms and seat cushion. Fabric, wood finish, or nailhead studs are all customizable with hundreds of designer combinations to choose from.

- Exposed Wood Leg

- Tapered Leg

- Attached Back

Specifications

Specifications

Product

Motion Type

Stationary

Motion Type

- Stationary

Dimensions

Height (bottom to top)

36.5" H

Height (bottom to top)

- 36.5" H

Width (side to side)

30.5" W

Width (side to side)

- 30.5" W

Depth (front to back)

67" D

Depth (front to back)

- 67" D

Arm Height

25"

Arm Height

- 25"

Seat Height

19.5"

Seat Height

- 19.5"

Seat Width

21"

Seat Width

- 21"

Seat Depth

50"

Seat Depth

- 50"

Style Elements

Custom Options

Custom Upholstery, Custom Finishes

Custom Options

- Custom Upholstery

- Custom Finishes

Leg / Base Type

Exposed Wood Leg, Tapered Leg

Leg / Base Type

- Exposed Wood Leg

- Tapered Leg

Design Style

Transitional, Traditional

Design Style

- Transitional

- Traditional

Fabric Options

Hundreds of fabric colors are available to special order.

Fabric Options

- Hundreds of fabric colors are available to special order.

Arm Type - Upholstered

English Arm

Arm Type - Upholstered

- English Arm

Back Cushion

Attached Back

Back Cushion

- Attached Back

Construction & Materials

Seat Support Description

Stretch web construction is strips of 2-inch wide elasticized webbing stretched and interlaced from front-to-back

and side-to-side in the seating area of the frame. These strips are covered with a 1/2-inch seat pad material

before the seat fabric is applied.

Seat Support Description

- Stretch web construction is strips of 2-inch wide elasticized webbing stretched and interlaced from front-to-back and side-to-side in the seating area of the frame. These strips are covered with a 1/2-inch seat pad material before the seat fabric is applied.

Origin

Made In the USA

Origin

- Made In the USA

Upholstery Frame Construction

To maximize the yeild and quality traits of this natural resource, wood is cut into smaller depths and layered

perpendicular to criss-cross the grain and add strength and rigidity. The glue is applied evenly between the slices,

then pressure is applied to ensure the glue is absorbed into the pores and cures to become a solid hardwood blank.

The layered hardwood blanks come in various depths, we use 7/8-inch, 1-inch, and 23/32 inches. Depending on

the frame requirements, two blanks may be glued together to make the finish depth requirement.

Layered hardwood is ideal for areas of the frame that will be covered by foam padding before fabric or leather

upholstery is applied, which provides strength and rigidity of the final product. The front rails, back rail, and top

rail are hardwood solids, purposely placed at the load beraing areas of the frame. And solid wood blanks are used

to ensure the intricacies of the carving details and/or machining requirements, and to highlight the wood grain

visibility once finished. To ensure a strong frame, the joints must fit snuggly wherein the glue cures to make a

single unit.

Upholstery Frame Construction

- To maximize the yeild and quality traits of this natural resource, wood is cut into smaller depths and layered perpendicular to criss-cross the grain and add strength and rigidity. The glue is applied evenly between the slices, then pressure is applied to ensure the glue is absorbed into the pores and cures to become a solid hardwood blank. The layered hardwood blanks come in various depths, we use 7/8-inch, 1-inch, and 23/32 inches. Depending on the frame requirements, two blanks may be glued together to make the finish depth requirement. Layered hardwood is ideal for areas of the frame that will be covered by foam padding before fabric or leather upholstery is applied, which provides strength and rigidity of the final product. The front rails, back rail, and top rail are hardwood solids, purposely placed at the load beraing areas of the frame. And solid wood blanks are used to ensure the intricacies of the carving details and/or machining requirements, and to highlight the wood grain visibility once finished. To ensure a strong frame, the joints must fit snuggly wherein the glue cures to make a single unit.

Padding & Ergonomics

The Ultra Down Cushion is comprised of a foam core wrapped with an extra soft foam layer, and sewn into a ticking filled with a luxurious blend of polyester fibers and

down/feather mixture. The down-proof

ticking is channeled to keep fibers and

feathers evenly dispersed.

Padding & Ergonomics

- The Ultra Down Cushion is comprised of a foam core wrapped with an extra soft foam layer, and sewn into a ticking filled with a luxurious blend of polyester fibers and down/feather mixture. The down-proof ticking is channeled to keep fibers and feathers evenly dispersed.

Item & Dimensions

Manufacturer

Lexington

Manufacturer

- Lexington

The Silverado Pleasanton Chaise Lounge, made by Lexington,

is brought to you by Johnny Janosik. Johnny Janosik is a local furniture store, serving the Delaware, Maryland, Virginia, Delmarva area. Product availability may vary.

Contact us for the most current availability on this product.

Collection Details

The direction of high-end interior design continues to take on a more casual aesthetic - particularly the traditional category. The look has evolved to incorporate clean architectural lines, transitional styling, statement hardware and an emphasis on comfortable seating. Silverado features classic styling that puts a current touch on traditional design. The collection is crafted from walnut veneers and mahogany solids in a rich walnut finish. Hand-wrought metal bases, in a maritime brass finish, reflect the work of an artisan’s hand, and select items hint of the exotic, with tiger-brown travertine tops.

The Silverado collection is an amazing option if you are looking for

Transitional furniture.

Our store serves the Delaware, Maryland, Virginia, Delmarva area.

Similar search terms: Rocker, Rocking Chair, Nursery Furniture, Nursery Rocking Chair, Glider, Nursery Glider, Glider Chair, Glider Rocker, Glider Rocking Chair, Glider Rocking Chair, Childrens Room Rocking Chair, Chair and a Half, Chair and a Half Recliner, Chair and a Half Sleeper, Chair and a Half with Ottoman, Big Chair, Oversized Chair, Chair and Ottoman, Ottoman Chair, Chair and Ottoman Set, Accent Chair, Chaise, Chaise Lounge, Small Chaise, Chaise Lounge Chair, Custom Chaise Lounge, Chaise Lounger, Double Chair, Exposed Wood Chair, Accent Chair with Wood Arms or Legs, Exposed Wood Seating, Exposed Wood Pieces, Wing Chair, Wingback Chair, Queen Anne Chair, Easy Chair, Fireplace Chair, Daybed

Reference #: 7943-77

Your cart looks happy!

Lexington

Silverado

Pleasanton Chaise Lounge

$2,399.00

You Might Also Need